Products

PRODUCTS CENTER

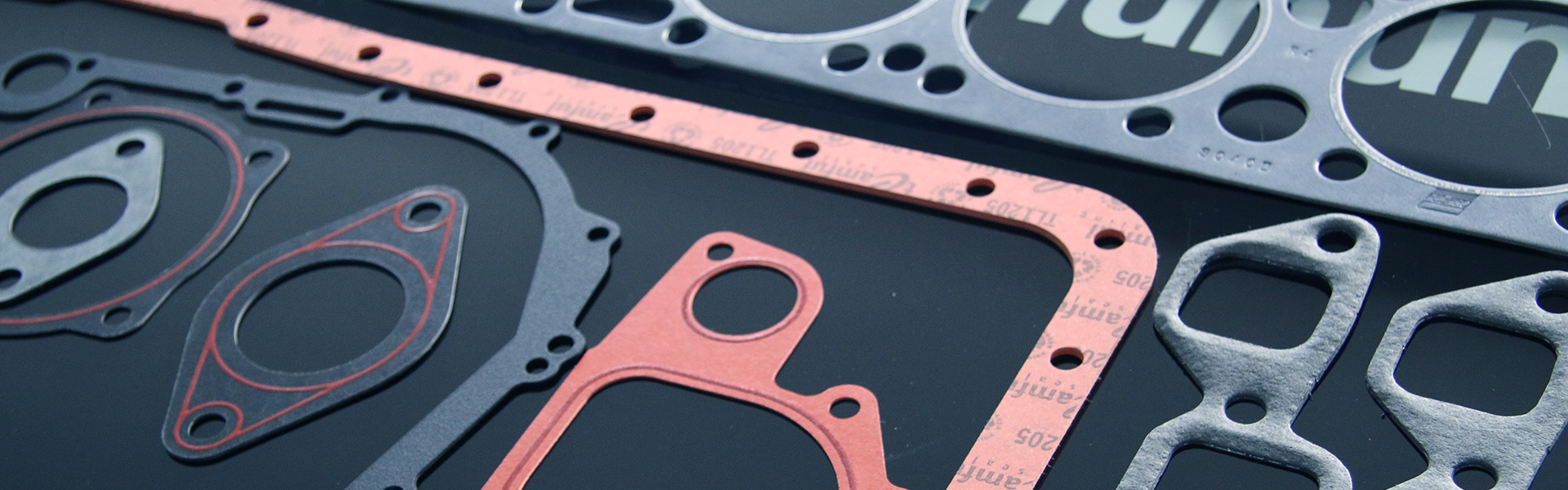

TL-GM-02○

summary: This product is our company's high-performance and environmentally friendly non-asbestos gasket material. The product is made of a combination of aramid fiber, nitrile synthetic rubber, kaolin and other fillers. It has good compressibility and high resilience, excellent air tightness and good anti-aging performance, as well as good resistance to acid and alkali liquid, reliable resistance to lubricating oil, fuel oil, steam, seawater, sewage medium sealing. It can be used for a long time for sealing the oil and water parts of various ship machinery, pipeline chemicals, engineering machinery, boiler steam and engines below 290°C.

category:

summary

This product is our company's high-performance and environmentally friendly non-asbestos gasket material. The product is made of a combination of aramid fiber, nitrile synthetic rubber, kaolin and other fillers. It has good compressibility and high resilience, excellent air tightness and good anti-aging performance, as well as good resistance to acid and alkali liquid, reliable resistance to lubricating oil, fuel oil, steam, seawater, sewage medium sealing. It can be used for a long time for sealing the oil and water parts of various ship machinery, pipeline chemicals, engineering machinery, boiler steam and engines below 290°C.

Physical properties

|

project |

Test standards |

index |

|

|

Density/g/cm³ |

ASTM F1315 |

≥1.56 |

|

|

Tensile strength/Mpa |

ASTM F152 |

≥9 |

|

|

Compression ratio/% |

ASTM F36 |

10 ~ 20 |

|

|

Rebound rate/% |

ASTM F36 |

≥50 |

|

|

Performance after impregnating IRM903 oil 149±2℃,5h |

Weight gain rate/% |

ASTM F146 |

≤35 |

|

Thickening rate/% |

ASTM F146 |

≤30 |

|

|

Performance after impregnating ASTM Fuel B 21~30℃,5h |

Weight gain rate/% |

ASTM F146 |

≤35 |

|

Thickening rate/% |

ASTM F146 |

≤30 |

|

|

Latex type |

Nitrile Butadiene Rubber |

||

seal

previous: TL2200-D △

next: WAG-TL1305 △