Technology R&D

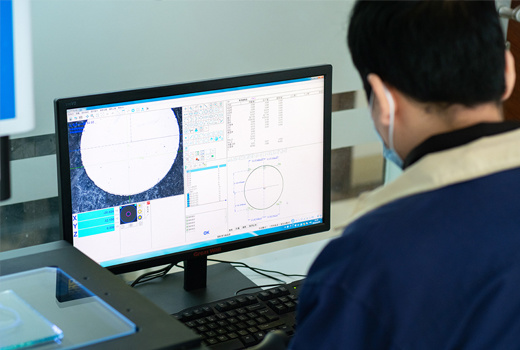

Testing Capability

After years of experience in material research and development and component testing, our company has established a relatively perfect capability to test physical, chemical, and mechanical properties of materials (in accordance with GB/ASTM/DIN testing standards) and the sealing/insulation performance of finished parts.

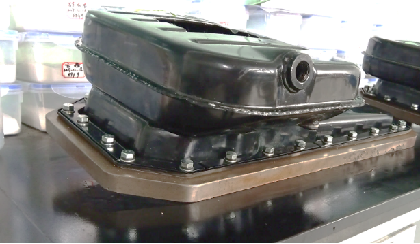

Test capability of finished parts: Full size data, Processing quality, Fujifilm surface pressure test, Bench test, High and Low temperature humidity cycle simulation test, etc.

Material performance testing capabilities: Rubber bonding strength, Rubber hardness, Compressibility, Recovery, Tensile Strength, Creep Relaxation, Oil resistance test, Specific medium resistance test, Oil and Gas sealing test, Thermal aging test, etc.

Product Testing and Validation Capabilities

-

ASTM Standard American Testing Standards ASTM F36 Compressibility and Recovery ASTM F37 Sealability Test ASTM F38 Creep relaxation rate ASTM F152 Tensile strength ASTM F146 Liquid Immersion Resistance test ASTM F495 Loss on ignition ASTM F607 Anti stick performance ASTM F1087 Dimensional stability ASTM 1574 High temperature compressive performance -

DIN/EN Standard European testing standards DIN 3535 Sealing test EN 13555 Compression deformation test -

Main testing standards for rubber coating materials ASTM D4541 Rubber Coating Pull-off Strength Test ASTM D3359 Rating Adhesion by Tape Test ASTM D2240 Rubber Property-Durometer hardness test ASTM D412 Vulcanized Rubber and Thermoplastic Elastomers Rubber- Tension Test ASTM D-573 Rubber – Deterioration in an Air Oven ASTM D-471 Rubber Property- Effect of liquids

OEM Customer technical support requirements

| Items | Teamful Sealing Capability |

|---|---|

| Material Analysis Technology | √ Operational GB\ASTM\DIN Testing standards |

| Laboratory Testing Capabilities | √ |

| In House Expertise | √ |

| Material Selection Technology | √ |

| Empirical Data Analysis | √ |

| Failure Mode Analysis | √ |

| Part Performance Prediction Analysis | √ |

| Long Term Creep Data | √ |

| Support for Gasket Engineering | √ |

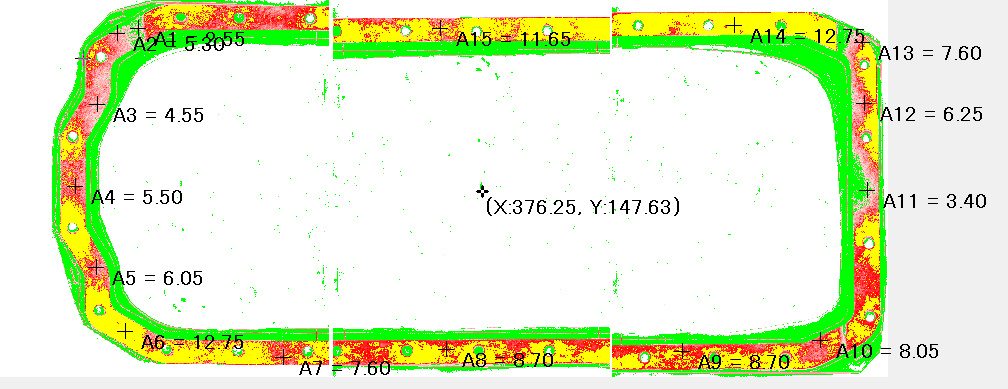

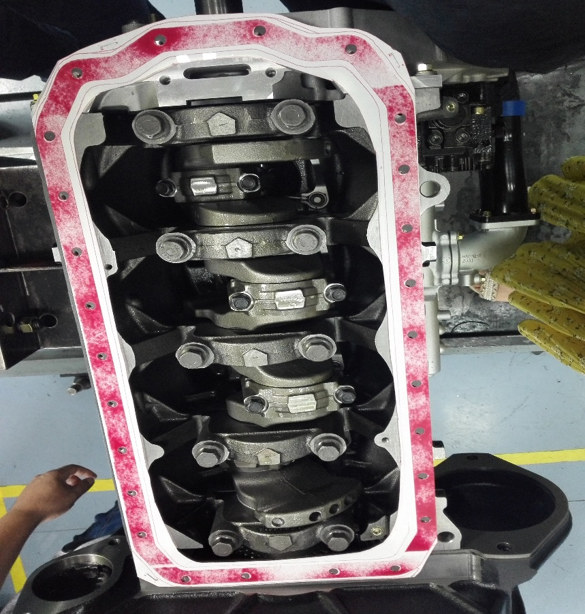

Surface pressure test and analysis of Fujifilm:Customer installation site (Before Material Improved)

Part Performance Test

|

|

|

| Oil-Pan Test Component | Sealing Performance Bench Test for different sealing medium |