Products

PRODUCTS CENTER

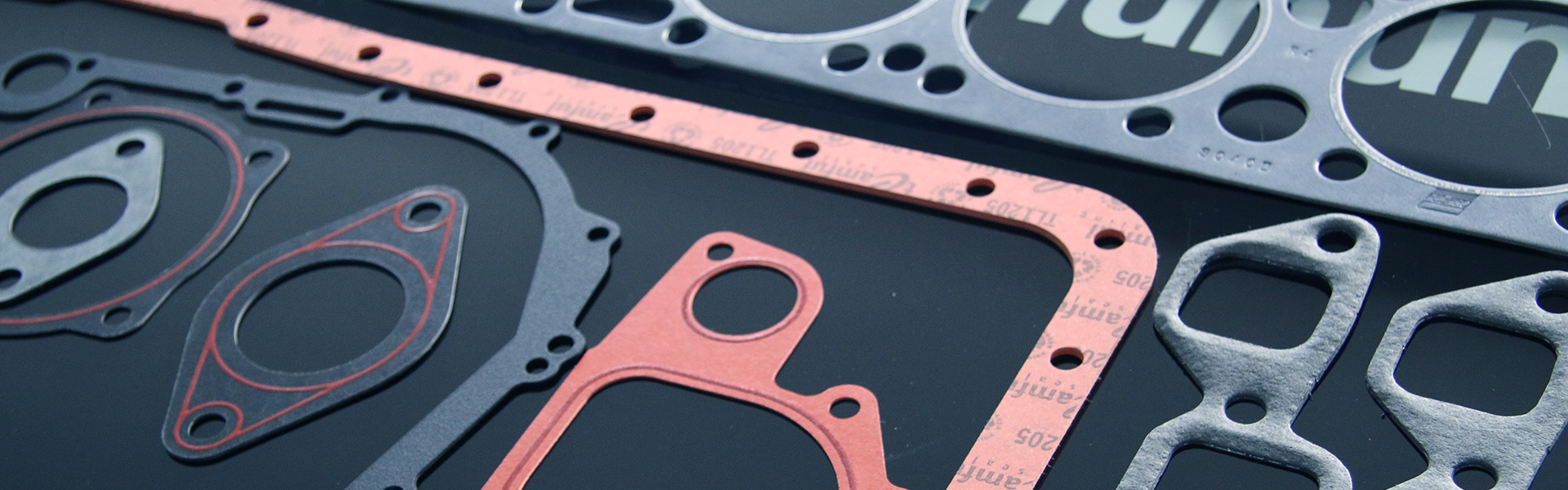

WAG-TL1310 #

summary: The product is a gray asbestos-free metal composite board, with a metal sprint composite board as the core board, and a two-sided composite TL1310 asbestos-free sealing material, which is suitable for making various internal combustion engine cylinder gaskets, intake and exhaust gaskets, carburetor gaskets and other high-pressure and high-temperature demand sealing part gaskets, as well as compressors, general machines and other sealing applications. It has good compressive resilience and bolt torque retention.

category:

summary

with a metal sprint composite board as the core board, and a two-sided composite TL1310 asbestos-free sealing material, which is suitable for making various internal combustion engine cylinder gaskets, intake and exhaust gaskets, carburetor gaskets and other high-pressure and high-temperature demand sealing part gaskets, as well as compressors, general machines and other sealing applications. It has good compressive resilience and bolt torque retention.

physical properties

|

project |

test criteria |

indicator |

|

|

density/g/cm3 |

ASTM F1315 |

2 ~ 3 |

|

|

compression ratio/% |

ASTM F36 |

10 ~ 35 |

|

|

rebound rate/% |

ASTM F36 |

≥ 20 |

|

|

loss on ignition/% 800°C, 1h |

ASTM F495 |

≤30 |

|

|

performance after impregnating IRM903 oil 23~30℃,22h |

weight gain rate/% |

ASTM F146 |

≤20 |

|

thickening rate/% |

ASTM F146 |

≤10 |

|

|

performance after impregnating ASTM Fuel B 23~30℃,22h |

weight gain rate/% |

ASTM F146 |

≤20 |

|

thickening rate/% |

ASTM F146 |

≤10 |

|

|

properties after impregnating distilled water 21~30℃,22h |

weight gain rate/% |

ASTM F146 |

≤15 |

|

thickening rate/% |

ASTM F146 |

≤10 |

|

seal

previous: WAG-TL1306△

next: WAG-TL2305△