Products

PRODUCTS CENTER

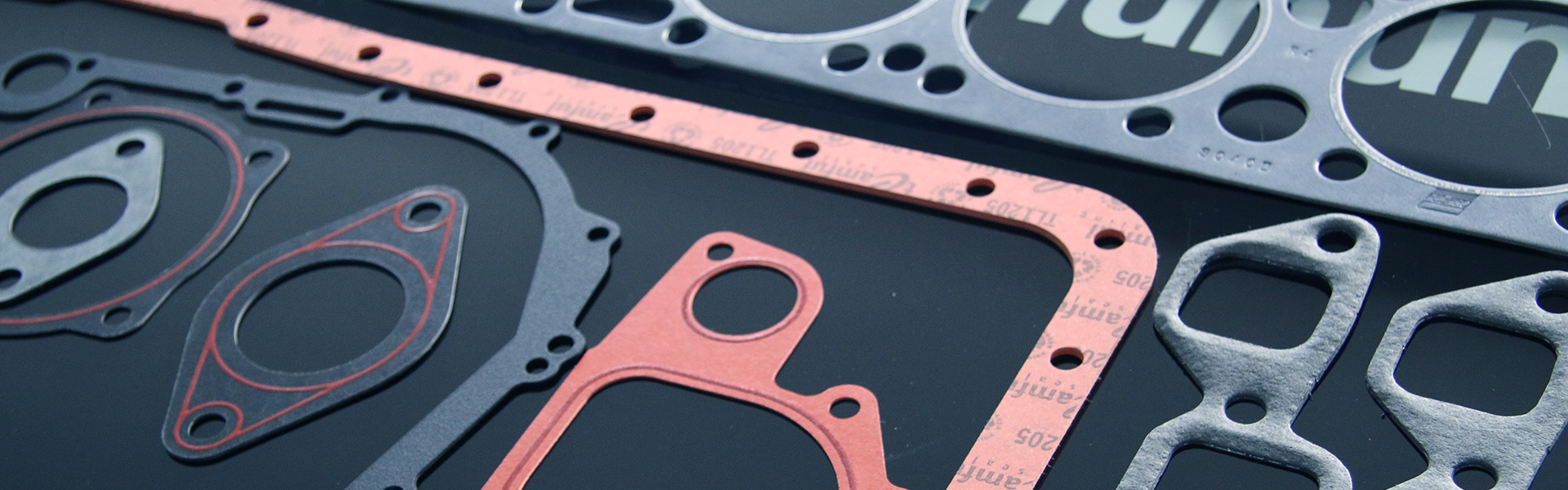

TL1205 ○

summary: The product is a red non-asbestos sealing gasket material, containing reinforced organic fiber, good oil resistance, high tensile strength, good compression rebound rate. The maximum clearance use temperature is 200°C.

category:

summary

The product is a red non-asbestos sealing gasket material, containing reinforced organic fiber, good oil resistance, high tensile strength, good compression rebound rate. The maximum clearance use temperature is 200°C.

|

project |

Test standards |

index |

|

|

Density/g/cm³ |

ASTM F1315 |

≥1.35 |

|

|

Tensile strength/Mpa |

ASTM F152 |

≥10.5 |

|

|

Compression ratio/% |

ASTM F36 |

10 ~ 20 |

|

|

Rebound rate/% |

ASTM F36 |

≥50.0 |

|

|

Performance after impregnating IRM903 oil 149±2℃,5h |

Weight gain rate/% |

ASTM F146 |

≤25 |

|

Thickening rate/% |

ASTM F146 |

≤15 |

|

|

Tensile strength/Mpa |

ASTM F146 |

≥8 |

|

|

Compression ratio/% |

ASTM F146 |

≤25 |

|

|

Rebound rate/% |

ASTM F146 |

≥40 |

|

|

After impregnating 10W-40 diesel engine oil, the performance is 149±2°C, 5h |

Weight gain rate/% |

ASTM F146 |

≤20 |

|

Thickening rate/% |

ASTM F146 |

≤8 |

|

|

Tensile strength/Mpa |

ASTM F146 |

≥9 |

|

|

Compression ratio/% |

ASTM F146 |

≤20 |

|

|

Rebound rate/% |

ASTM F146 |

≥40 |

|

|

Performance after impregnating ASTM Fuel B 21~30℃,5h |

Weight gain rate/% |

ASTM F146 |

≤20 |

|

Thickening rate/% |

ASTM F146 |

≤15 |

|

|

Performance after impregnating coolant 149±2℃,5h |

Weight gain rate/% |

ASTM F146 |

≤35 |

|

Thickening rate/% |

ASTM F146 |

≤20 |

|

|

Latex type |

|

||

seal