Products

PRODUCTS CENTER

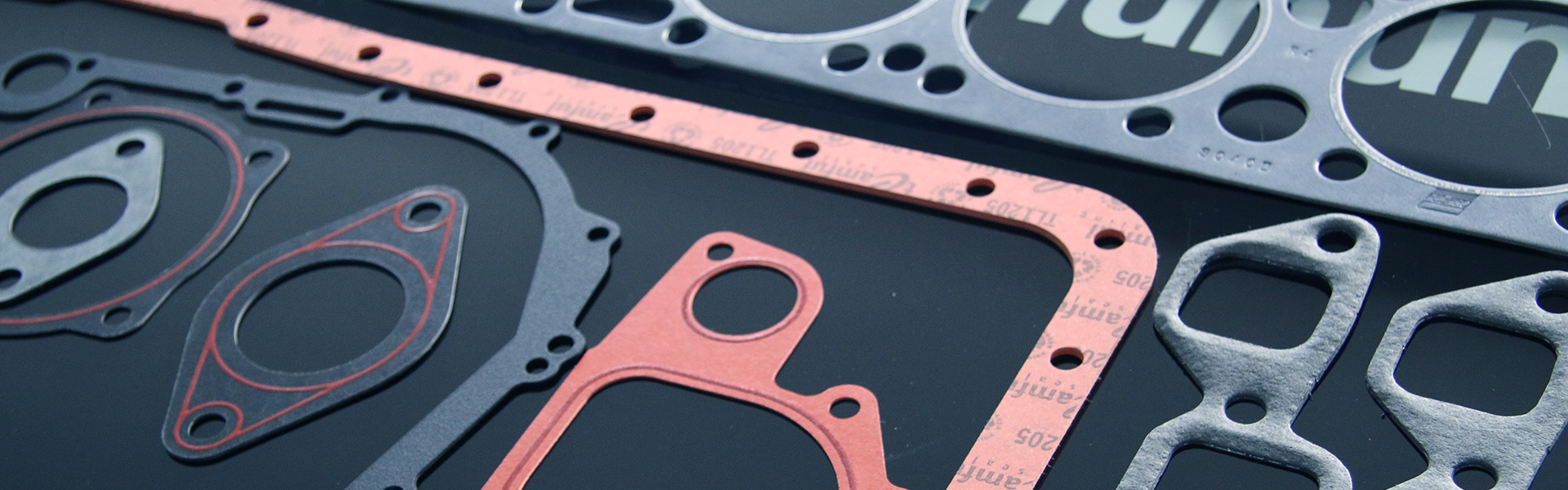

GN3025‐SPCC

summary: The material is a new sealing material that uniformly coats a rubber layer on the surface of the metal substrate through a specific production process

category:

summary

The material is a new sealing material, which is uniformly coated with a rubber layer on the surface of the metal substrate through a specific production process; The material has good heat resistance, durability and a very low pressure set. Compared to traditional non-metallic sealing materials, this material has a relatively long service life, so it is often used in environments with higher pressures, higher temperatures and more demanding sealing requirements.

Technical indicators

|

project |

Indicator requirements |

|

|

Rubber type |

nitrile rubber |

|

|

Metal substrate |

SPCC |

|

|

appearance |

Matte semi-black, smooth |

|

|

Total thickness(mm) |

0.30±0.02 |

|

|

Metal substrate Thickness(mm) |

0.25±0.01 |

|

|

Rubber layer thickness(mm) |

0.025±0.005(Single-sided) |

|

|

Maximum operating temperature(°C) |

≤150℃ |

|

|

Rubber adhesion ASTM-D3359 |

100% no shedding |

|

|

Adhesive layer pull-off strength (Mpa) ASTM-D4151-09 |

≥1.4 |

|

|

Base hardness (HV) |

120 ~ 160 |

|

|

Unburned test |

Rubber hardness(A) ASTM D-2240 |

70 ~ 80 |

|

Tensile strength (Mpa) ASTM D-412 |

≥8 |

|

|

Elongation (%) ASTM D-412 |

≥200 |

|

|

Heat aging 70 hours 100℃ |

Change in hardness (%) ASTM D-573 |

—15 ~ 15 |

|

Change in tensile strength (%) ASTM D-573 |

—30 ~ 30 |

|

|

IRM903# oil, dipped Oil volume change rate (%) ASTM D-471 |

≤40 |

|

Rubber

strength

previous: GF4035‐SPCC

next: BF3025‐304