Products

PRODUCTS CENTER

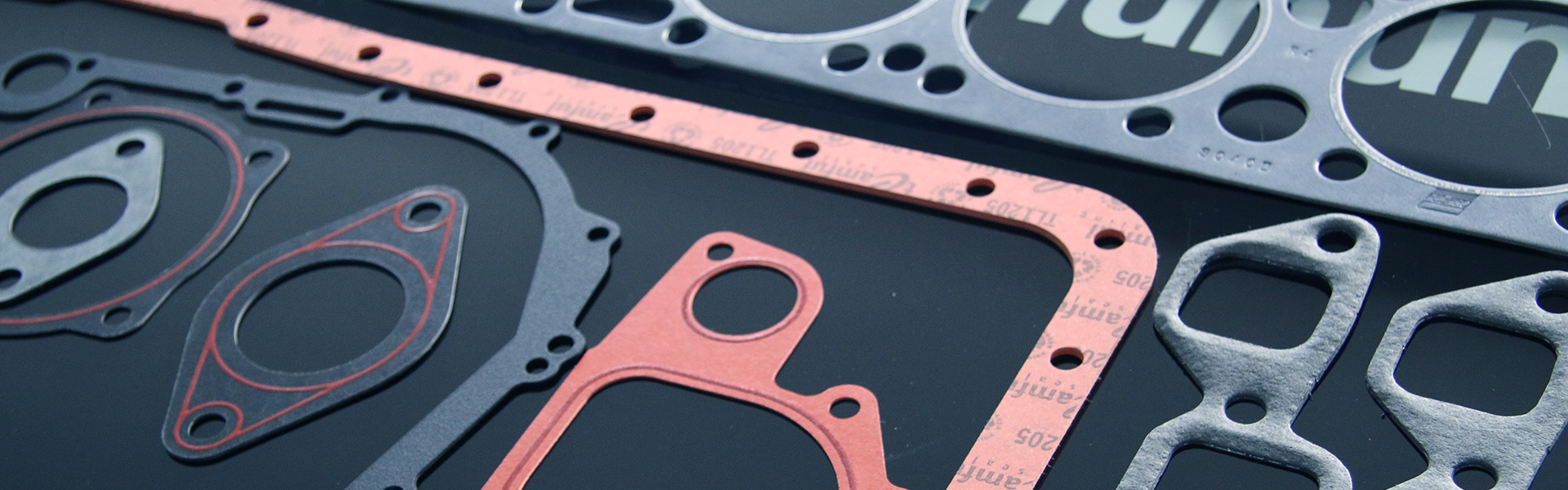

Asbestos-free sealing material

summary: The environmentally friendly non-asbestos sealing products independently developed by Tianfu Company are environmentally friendly products with zero asbestos content, using water as the dispersion medium, and are made by pulping, raw material mixing, copying, and roll vulcanization process. Compared with the rolling method production process, the long mesh copying method production process does not use any organic solvents and environmentally unfriendly materials, with water as the medium, the material forming structure is uniform and stable, the performance is excellent, the feel is soft and delicate, and it can be produced in rolls or cut into specification sheets. The non-asbestos material by copying method has excellent compressive resilience performance, and the sealing effect can be achieved by using relatively small stress.

category:

summary

-Recommend to use for OEM Fuel,Oil,Air sealability application.

--TH-01 already get global approval from Cummins(CES24231)TH-O1

The environmentally friendly non-asbestos sealing products independently developed by Tianfu Company are environmentally friendly products with zero asbestos content, using water as the dispersion medium, and are made by pulping, raw material mixing, copying, and roll vulcanization process. Compared with the rolling method production process, the long mesh copying method production process does not use any organic solvents and environmentally unfriendly materials, with water as the medium, the material forming structure is uniform and stable, the performance is excellent, the feel is soft and delicate, and it can be produced in rolls or cut into specification sheets. The non-asbestos material by copying method has excellent compressive resilience performance, and the sealing effect can be achieved by using relatively small stress.

As one of the leading domestic non-asbestos sealing material R & D enterprises, Tianfu Company has more than 20 years of R&D and application experience in the research and application of non-asbestos sealing materials and gaskets by copying method. Our materials fully meet the strict environmental protection standards of European and American countries, and are not only used in major domestic engine companies, but also obtained product certification and supporting applications of many internationally renowned engine brands.

| material series | commonly used grade | temperature resistance | typical density | material composition | compositionapp recommendations | |

| Series | Grade Number | highest instantaneous, °C | Typical Density (g/cc) | fiber fiber | latex Rubber Binder | Recommend Application |

| TL11 series | TL1100 □ | 150 | 1.15 | Cellulose cellulose fiber | NBR | Aftermarket Low Cost Application Economical repair market |

| TL1102 △ | 150 | 1.0 | Cellulose cellulose fiber | NBR | ||

| TL1104 ○ | 150 | 1.0 | Cellulose cellulose fiber | NBR | ||

| TL1105 ○ | 150 | 1.0 | Cellulose cellulose fiber | NBR | ||

| TL1107 △ | 150 | 1.3 | Cellulose cellulose fiber | NBR | ||

| TL12 series | TL1204 ○ | 200 | 1.45 | synthetic synthetic fibers | Fully Cured NBR | General use for Middle-end application General purpose mid-range sealing applications |

| TL1205 ○ | 200 | 1.4 | synthetic synthetic fibers | Fully Cured NBR | ||

| TL13 series | TL1305 △ | - | 1.15 | Mineral mineral fiber | NBR | High Temperature Resistant Facing paper High temperature resistant composite board surface |

| TL1306 △ | - | 1.15 | Mineral mineral fiber | NBR | High Temperature Resistant Facing paper High temperature resistant composite board surface | |

| TL2305 △ | - | 1.15 | Aramid aramid fiber | NBR | High Temperature Resistant Facing paper High temperature resistant composite board surface | |

| TL1310 # | - | 1.15 | Heat-resistant carbon fibre | NBR | High Temperature Resistant Facing paper High temperature resistant composite board surface | |

| TL15 series | TL1515 △ | 290 | 1.5 | Aramid aramid fiber | Fully Cured NBR | High-end Heavy Duty Engine Application High-end heavy-duty engine applications |

| TH-01 △ | 290 | 1.55 | Aramid aramid fiber | Fully Cured NBR | ||

| TL16 series | TL1601 △ | 180 | 1.3 | Reinforced Cellulose cellulose cellulose fiber | Fully Cured NBR | General use for Middle-end application General purpose mid-range sealing applications |

| TL17 series | TL1703 △ | 200 | 1.3 | Reinforced Cellulose cellulose cellulose fiber | SBR | Control swelled, General use for Middle-to-high end application Oil puffed type, general medium and high-end applications |

| TL1706 △ | 200 | 1.4 | Reinforced Cellulose cellulose cellulose fiber | SBR | ||

| TL22 series | TL2200 △ | 150 | 1.45 | synthetic synthetic fibers | Fully Cured NBR | General use for Middle-end application General purpose mid-range sealing applications |

| TL2200-D △ | 150 | 1.3 | synthetic synthetic fibers | Fully Cured NBR | General use for Middle-end application General purpose mid-range sealing applications | |

| GM series | TL-GM-02○ | 290 | 1.6 | Aramid aramid fiber | Fully Cured NBR | High-end Medium Duty Engine Application High-end midsize engine applications |

| WAG series | WAG-TL1305 △ | 400 | 2.0 ~ 3.0 | Mineral mineral fiber | NBR | Metal reinforced sheet, High temperature resistance High temperature resistant metal reinforced composite panel |

| WAG-TL1306△ | 400 | 2.0 ~ 3.0 | Mineral mineral fiber | NBR | ||

| WAG-TL2305△ | 400 | 2.0 ~ 3.0 | Aramid aramid fiber | NBR | ||

| WAG-TL1310 # | 800 | 2.0 ~ 3.0 | Mineral mineral fiber | NBR | ||

Fiber

series

cellulose